Unterpremstaetten, Austria, ams AG, a leading provider of high performance analog ICs and sensors today released the AS8515 reference design implementing a complete automotive Intelligent Battery Sensor (IBS) based on its highly accurate AS8515 data acquisition front end.

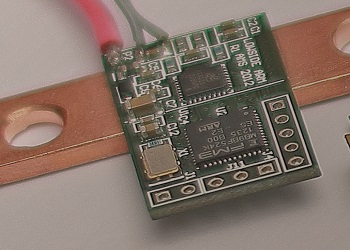

The IBS design from ams is suitable for monitoring the state of charge (SOC) and state of health (SOH) of the latest lithium-iron-phosphate automotive batteries as well as conventional AGM (lead-acid) batteries. The IBS’s measurement front end is provided by the AS8515, which takes precise, synchronized measurements of the battery’s current and voltage, and of the board’s temperature, and outputs them as a digital signal. The measurement data are processed by a Fujitsu ARM Cortex-M3 microcontroller to provide accurate readings for any type of 12V battery.

The reference design, which is fully documented and available as part of a development kit, is production-ready, and may be used by automotive manufacturers as an off-the-shelf template for an IBS system. Unlike fixed-architecture system-in-package offerings from competitors, the ams reference design also gives the user freedom to make their own choice of microcontroller.

Software provided with the ams IBS reference design demonstrates SOC calculation using the coulomb-counting method and calculation of battery impedance triggered whenever the load changes by more than 5A. This software can easily be ported to any microcontroller of the developer’s choice, including other ARM Cortex-M series devices.

The AS8515 has an integrated LIN transceiver, and the IBS sensor module can operate as a LIN slave in automotive systems. The reference design includes a separate LIN master board containing a LIN controller and USB controller, which enables the developer to control and configure the sensor module via a GUI (for Windows PC) supplied by ams.

The IBS module draws on ams’s expertise in the design of precise and sensitive analog circuits, producing extremely accurate battery measurements: accuracy of current measurement is a typical ±0.5% over the entire signal range, and typical voltage measurement accuracy is better than ±0.1% over a temperature range of -40°C to +115°C. Linearity is better than 0.01%.

The efficient ARM Cortex-M3 core in the Fujitsu MB9B520K microcontroller helps contribute to impressive power consumption figures, with the entire sensor module drawing just 8mA in normal operation and 87µA in stand-by current monitoring mode.

“Competitors’ IBS systems trap automotive manufacturers in a fixed architecture that compels them to use the outdated microcontroller integrated in the supplier’s package. The ams solution is better because it separates the sensor device from the microcontroller, enabling developers to continually update the microcontroller in their IBS design while retaining the proven ams measurement front end,” said Bernd Gessner, vice-president and general manager of the automotive business unit at ams. |